Samba 3.5″

The Unitronics Samba 3.5” is a medium sized PLC that offers simple process control (2 auto-tuning PID loops) but with up-to-the-minute, visually impressive HMI features, including a 4:3 aspect colour touch screen. The unit includes a built-in RS232 port (2 more ports can be added if required) and 20 on board I/Os.

Control and Programming Capability

The Samba 3.5” has 2 independent PID loops, an application memory of 112K and a data table capacity of 32K RAM and 16K Flash. It is therefore ideal for simple processes with relatively few variables. As with all Unitronics PLCs, the Samba can be programmed using free Ladder Logic software, as well as having access to a library of graphs and trends, alarms and text strings for multi-lingual support.

HMI Features

The HMI capability of the Unitronics Samba belies its processing power. It has a 3.5 inch (320×240 pixels) 16 bit colour touch screen in a 4:3 format.

The HMI panel is a flat screen with no operator panel keys. User controls therefore need to be programmed into the display screen area, resulting in completely context dependent user input. The software includes access to a library of ready-to-use graphical HMI elements, including buttons and keys, as a well as a virtual on-screen keyboard when data entry is required from the user. The appealing colour screen and ability to tightly control user input, means that the Samba PLC can be used for both industrial and semi-industrial applications involving non-technical users.

Comms Capabilities

The Samba 3.5” supports a wide range of comms including SMS, RS232/RS485, Ethernet, MODBUS, CANbus, UNIcan etc. It also supports the DF1 Slave protocol, enabling the Samba to be easily integrated into a Master-Slave network.

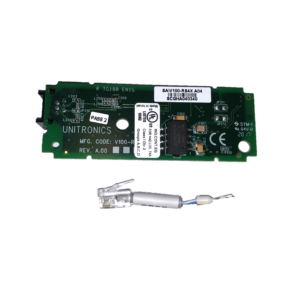

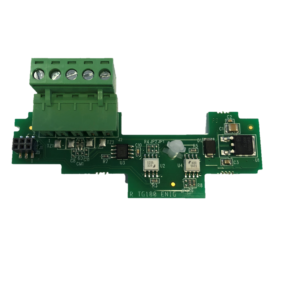

The Samba 3.5″ includes a built-in RS232/485 port for programming or communication. Up to 2 additional ports can be added – pick from RS232/485, Ethernet and CANbus.

I/O Options

The Samba 3.5” is provided with up to 20 on-board I/Os – 10 digital inputs, 2 analogue outputs and a further 8 outputs which can be either relay or transistor depending on model choice. The digital inputs/outputs can include temperature, weight, high speed counter or shaft encoder. Additional remote I/O expansion is available via CANbus.

SM35-J-R20 Samba 3.5″ touch screen PLC, 10 Digital, 2 D/A Inputs, 8 Relay Outputs

SKU: UN-SM35-J-R20

£272.86 Add to basket

SM35-J-T20 Samba 3.5″ touch screen PLC, 10 Digital, 2 D/A Inputs, 8 Transistor Outputs

SKU: UN-SM35-J-T20

£272.86 Add to basket